The AC-250 series are tabletop/floor standing automatic cutters with high performance. This is a versatile cutting machine designed for sectioning an extremely wide range of materials, such as metals, fasteners, rocks and ceramics, polymers, composites, electronics, semiconductors, biomaterials, etc. The machine integrates the optimized precision cutting technology with advanced control system to provide excellent cut quality and high throughput.

◆ Powerful motor to reduce cutting time and provide high productivity

◆ Smart feed. The machine can adjust the feed speed in real time with the load changes

◆ Cutting modes: Y-continuous, Y-pulse, Z-continuous, Z-pulse, slicing (different model, different cutting mode)

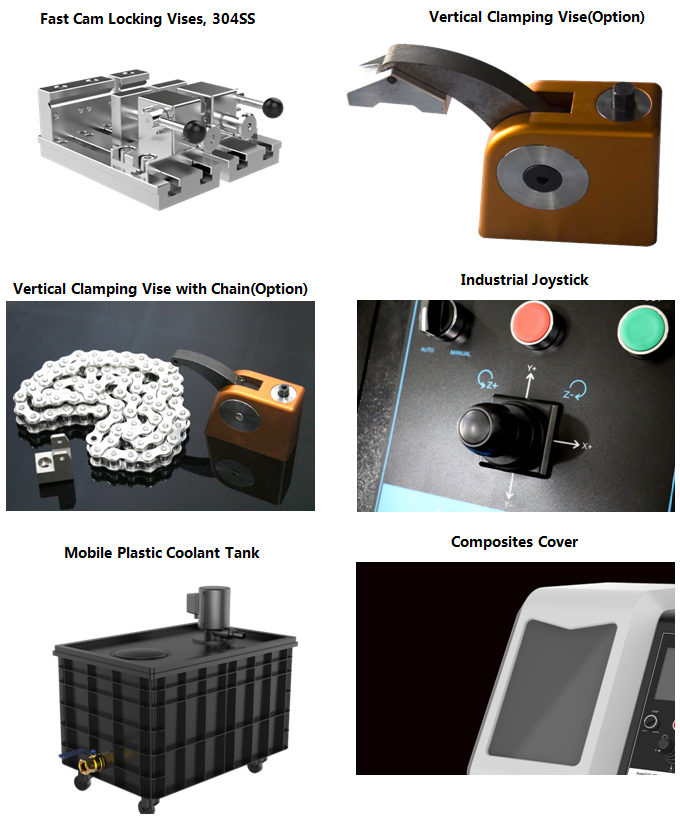

◆ Versatile industrial joystick with X, Y, Z axis. Easy to use

◆ 8 inch color touchscreen for simple operation and user friendliness

◆ Electrical brake for faster stopping of the blade

◆ Chamber illumination with LED

◆ Aluminum casting base, powder coated

◆ T-slot Table made of stainless and aluminum alloy

◆ Fast Cam Locking Vises, made of 304 stainless steel

◆ Left cover made of composites by integral molding

◆ Mobile plastic recirculation coolant tank

◆ Independent pump for cleaning the chamber

◆ Optional laser alignment aid

Description | AC-250XYZ | AC-250YZ | AC-250Z |

Y Feed | Automatic | ||

Z Feed | Automatic | Automatic | --- |

X Feed | Automatic | ○Manual | ○Automatic○Manual |

Cutting mode | Continuous, Pulse | Continuous, Pulse | Continuous, Pulse |

Blade(mm) | 250*32*1.5 | ||

Blade speed (rpm) | 500-3000 | ||

Table Dimensions (WxD,mm) | 279*260 | ||

X Travel | 60mm | ||

Cooling | Automatic/manual | ||

Main Motor | 2.2KW | ||

Power | 110/220V AC, 50-60Hz, 1 Phase | ||

Accessories | |||

Diamond Blade | ○ | ○ | ○ |

SiC blade | ○ | ○ | ○ |

Alumina Blade | ● | ● | ● |

Fast Cam Locking Vises | ● | ● | ● |

Vertical Clamping vise | ○ | ○ | ○ |

Laser alignment aid | ○ | ○ | ○ |

Plastic tank | ● | ● | ● |

Plastic tank with magnetic filter | ○ | ○ | ○ |

Cutting fluid | ○ | ○ | ○ |

Centrifugal separator | ○ | ○ | ○ |

Base Bench | ○ | ○ | ○ |

●standard○option

Derechos de autor © 2018Sinowon Innovation Metrology Manufacture Limited. | Reservados todos los derechos 粤ICP备16062806号

Hola, por favor, deje su nombre y envíelo por correo electrónico antes de chatear en línea para que no extrañemos su mensaje y nos pondremos en contacto con usted sin problemas.